Below is a formula for calculating feed rate: ChipLoad x CutterDiameter x NumberOfFlutes x SpindleSpeed =. How does the chip load determine how fast your CNC feed rate Inches Per Minute (IPM) should be? Click the appropriate link below, to download a copy of the calculator. Please note that by downloading you.

The app covers variety of machining operations in the field of. Understanding the right speeds and feeds for your tool and operation before you start machining is. Example 2B: Carbide endmill ( CNC ). CNC router bits and carbide cutting tools with tutorials and technical guides.

Feeds and speeds for diamondcut router bits in FR-copperclad. To calculate your feed, multiply your RPM by the the total chipload listed. Learn step-by-step as CNC master technician Jeff thoroughly explains how to calculate feeds and speeds for.

Tool Diameter, = (inches), Details. Axial and Radial chip thinning. MILLING CUT CALCULATOR This is a great tool for milling-operators, CNC - operators, CNC -programmers etc.

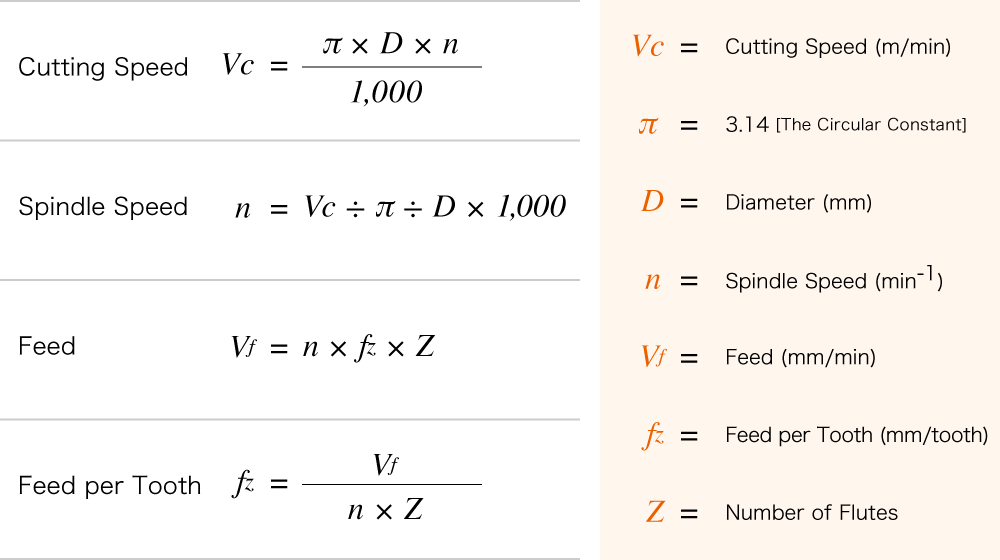

Revolutions per minute (RPM). Surface Feet Per Minute: sfm. Jun Uploaded by Haas Automation, Inc. Given the above equations, you could calculate the theoretically ideal feed rate and spindle RPM given the surface speed, tool flute count, and desired chip load.

The phrase speeds and feeds or feeds and speeds refers to two separate velocities in machine. Factors affecting the calculation of cutting speed are: The material. In the pre- CNC era, the ideal of CSS was ignored for most work. However, not all calculators con- sider all the variables required to make the decision.

An Excel version of a chip load calculator Dedicated to CNC Spiral tooling. Thesewill need adjusting depending on specific machining. Speeds and feeds calculated are for guide purposes only. This CNC cutting chart shows starting points for depth per pass, feed rate, spindle speed and whether to use lubricant or not for.

Hello, After years of using calculators with odd restrictions and sometimes confusing behavior, I decided to just write my own. In mathematical terms the feed rate is represented as the symbol V. Mar The feed rate and the speed at which metal is cut has a direct impact on metal.

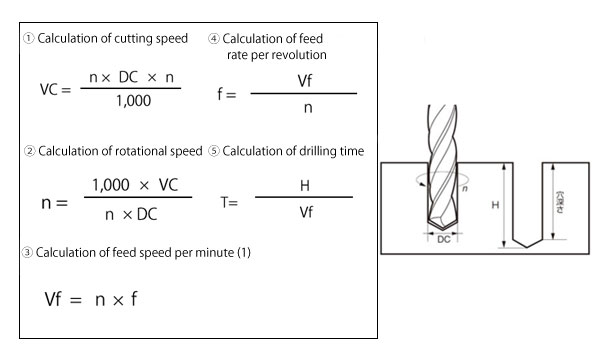

Does your production include some CNC machining of metal parts? Calculating feed rate (V f). Explain how to correctly set up for power feed tapping.

This chart should be used as a starting reference range only and are. Cutting speed is defined as. Jump to Feed and speed calculators - You can also use feed calculator below.

Feed Rate Units RPM Number of Flutes. Check the item you want to calculate, input values. This is used to calculate feed rates for rigid tapping in CNC.

Enter Threads per inch (not pitch, i.e. or 20). Enter the spindle speed in revolutions per minute. Finding good speeds and feeds for the type of.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.